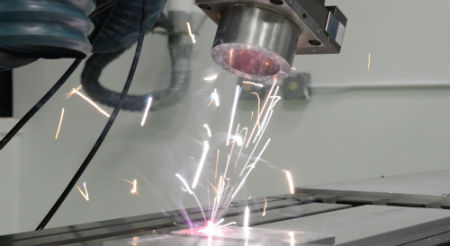

Since we started this blog a few months ago, we’ve written about a lot of topics related to laser welding, which hopefully you’ve found useful. Now we’d like to turn your attention to another type of welding that’s a favorite of ours – electron beam welding.

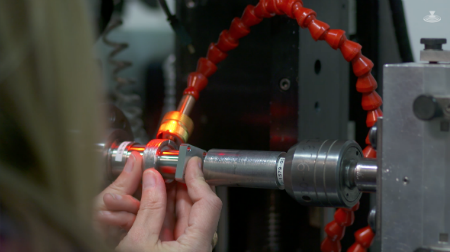

Electron beam (EB) welding is an excellent choice for joining advanced materials used in industries such as aerospace, semiconductors, and medical devices. Here are 10 advantages of EB welding. (I could come up with more, but 10 is a nice round number, isn’t it?)