Oh boy. I’m sure I’ll get flak from someone for tackling this one, but here goes anyway.

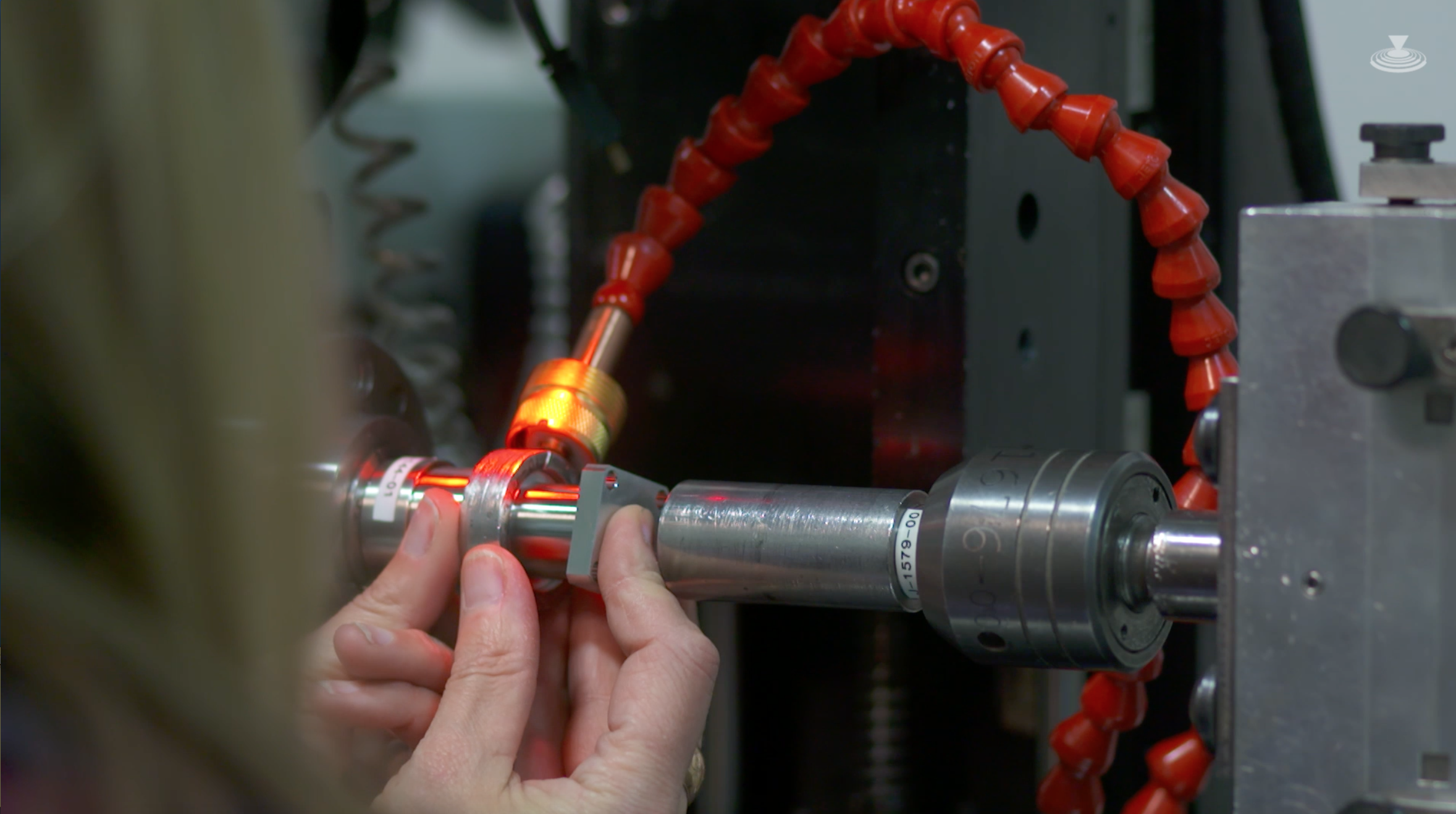

Let’s talk about tolerances for welding. For this post, we’ll focus only on the weld joint and follow the common theme of customer-vendor interaction.

Customer: “What kind of gap range can you tolerate in a weld?”

Vendor: “What kind of weld? Process? How deep? How wide? Material? Filler?”

Customer: “That doesn’t matter yet, I just need to know how big of a gap you can weld and how much it can vary.”